Add: 21-2#, Xinggang Road, Huangshigang Industrial Zone, Huangshi City, Hubei Province

Tel: 0086-13597667790

Contact: Kate Yan

E-mail: kate@hongxingmold.com

Website: m.fne886.cn

Details

The extrusion process produces objects with set cross-sectional profiles by forcing material through a die with the desired cross-section. Its ability to create highly intricate cross-sections and deal with brittle materials because the material only experiences compressive and shear stresses are two of its key benefits over other production procedures. Additionally, it produces excellent surface polish and allows for a great deal of form freedom during the design process.

A comparable procedure is drawing, which involves pulling the material through the die using the material’s tensile strength. It can only be used for simpler shapes since it restricts the change to a single step; multiple steps are typically required. The primary method for producing wire is drawing. Also frequently drawn are metal bars and tubes.

Extrusion can be continuous or semi-continuous, theoretically yielding endless lengths of material (producing many pieces). Either hot or cold materials can be used. Metals and polymers, along with ceramics, concrete, and food products, are among the items that are frequently extruded. Extrudates is the broad term for the effects of extrusion.

Hollow cavities inside extruded material, often known as “hole flanging,” cannot be created with a direct flat extrusion die since there would be no means to support the central barrier of the die. Instead of starting with a shape profile that helps the main section, the die takes on the form of a block with depth.

The hanging center parts are supported from the back of the die as the internal die shape varies along its length into the final shape. The material flows around the supports and fuses to achieve the ideal closed shape. Metals can also get stronger through extrusion.

Some of the well-utilized characteristics of extrusion include:

Extrusion is a process for compacting metal. A piston or plunger is used in this procedure to apply a compressive force to the workpiece. A billet or ingot (a metal workpiece of conventional size) is offered initially.

This billet is placed in an extrusion press, heated during hot extrusion, or left at room temperature. The metal is placed in a cylinder and pressed by a piston in the extrusion press, which is similar to a piston-cylinder mechanism. A die is attached to the cylinder’s upper portion.

A plunger installed in the press immediately applies a compressive force to this component, forcing the billet to die. The die is the opening for the required cross-tiny section. The worked metal can flow through the die and take on the desired shape thanks to the solid compressive force. The extruded item is then removed from the press and heated to improve its mechanical qualities.

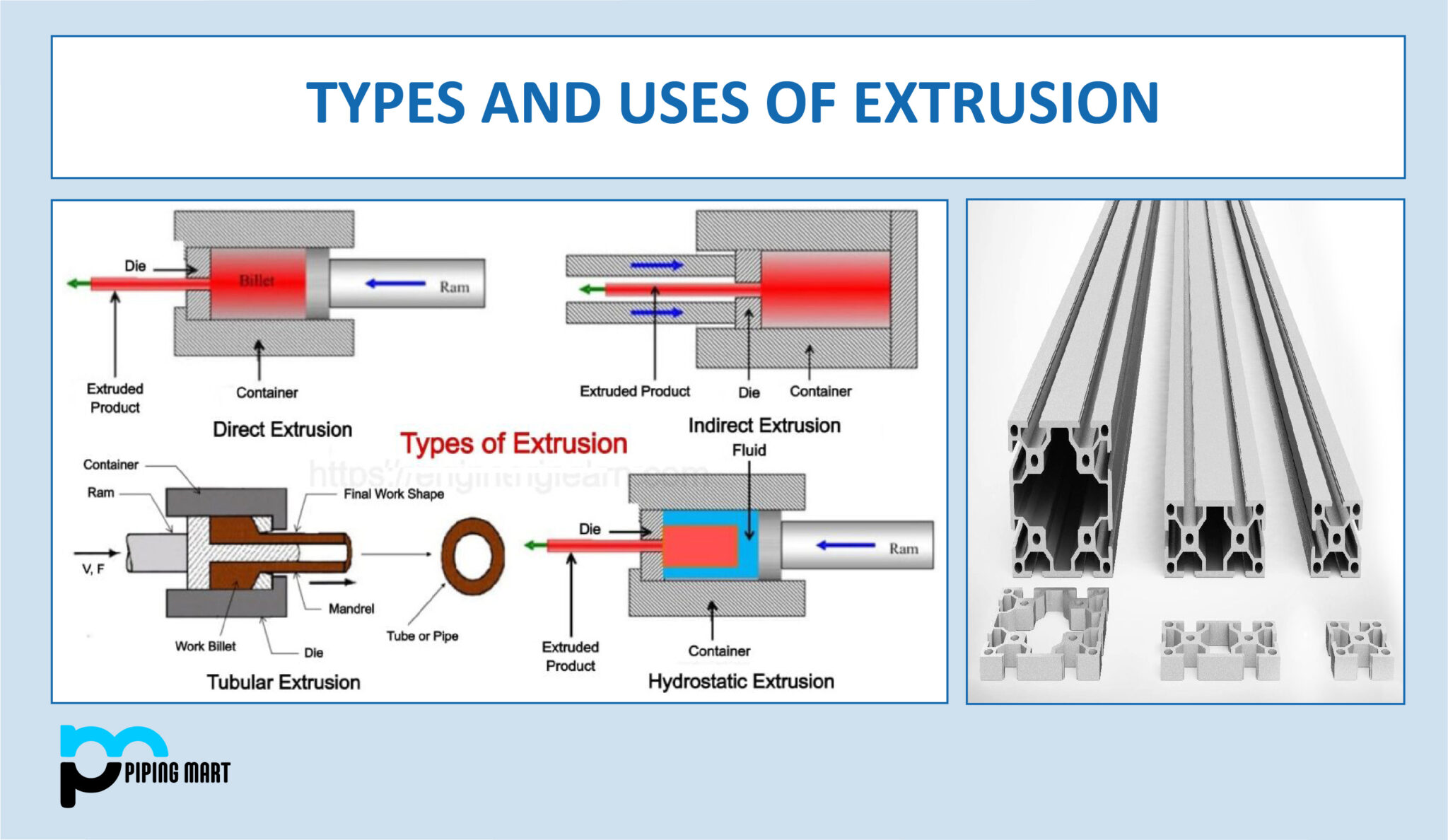

Depending on factors such as the direction of the extrusion flow, the substance used to apply force, the operating temperature, etc., metal extrusion can be divided into the following groups.

The hot extrusion technique is the most widely used for creating items with a set cross-sectional profile. By performing the extrusion process at a higher temperature, the materials are kept from hardening during processing, and forcing the material through the die is simplified.

In general, horizontal hydraulic presses with a tonnage range of 250–12,000 tonnes are used to accomplish large-scale hot extrusion. In this case, lubrication is necessary due to the pressure range of 30 to 700 MPa (4,400 to 102,000 psi).

For extrusions at higher temperatures, glass powder can be used as lubrication; oil or graphite can be used for extrusions at lower temperatures.

Hot extrusion has some limits due to the cost of the extrusion machinery and the upkeep of those devices, even if hot extruded material is highly desirable. Following are the two distinct types of hot extrusion.

The most typical form of extrusion is direct extrusion, often known as forward extrusion. It starts by placing a fake block behind a heated billet in a press cavity container (only for hot extrusion).

The mechanical or hydraulic ram forces the material into the die. While the portion is still hot, it is stretched to straighten it. Core Materials does a great job of animating this process.

Molten glass is used as a lubricant in direct extrusion to alleviate the high friction brought on by steel at higher temperatures, while lubricants containing graphite powder are used for lubrication at lower temperatures. In hot extrusion, the dummy block is utilized to shield the pressing stem’s (punch or ram) tip.

A small part of the billet, known as the “butt end”, cannot be forced through the die opening as the punch concludes its stroke.

The material that needs to be extruded in this process is in the shape of a block. It is heated to the necessary temperature before being moved into a chamber.

A die with an opening shaped like the cross-section of the extruded goods is mounted in the front part of the chamber. A follower pad and a ram provide pressure from behind the material block.

The heated material is required to pass through the die opening as a long strip with the requisite cross-section since the chamber is completely closed on all sides. Although the procedure appears straightforward, the friction between the material and the chamber walls must be reduced using proper lubrication.

It is challenging to find a suitable lubricant since steel must be heated to a high temperature before extrusion. By lubricating with molten glass, the issue is identified. As a lubricant, oil and graphite are combined when the lower temperature range is employed.

Benefits of Direct Metal Extrusion include

Direct Metal Extrusion Drawbacks comprise

To force the material through the die during indirect extrusion, the die is moved toward the billet inside the cavity by the hydraulic ram, which is at the end of the device. Because the static billet container creates less friction on the billet, this method uses less power. When the extrudate departs from the die, it is challenging to support the extruded portion.

The setup is carried out precisely. The chamber is filled with a hot metal block. Except for the entrance, it is surrounded by container walls on all sides, where the material is pressed against a ram bearing a die.

The material must flow through the aperture in the die when the ram presses backward. The ram is made hollow to allow the extruded metal bar to flow without being obstructed.

Since the material flow in this process is in the opposite direction from the movement of the ram, it is known as a backward extrusion process. The material flow and ram movement in the forward extrusion process were in the same direction.

Indirect Metal Extrusion Benefits are

Indirect metal extrusion drawbacks include

Extruders and extrusion equipment are used to conduct the cold extrusion process, which is done at ambient temperature or a moderately high temperature. These specific devices and machines were created using cutting-edge extrusion technology.

The process of moulding cold metal by striking a slug is known as cold extrusion. The metal is pushed upward around the punch during this blow, which is made with a punch (in an enclosed cavity). Extrusion pressing, cold forging, cold pressing, and impact extrusion are additional names for this procedure.

This type of extrusion is further classified as

By making the chamber or cavity smaller than the billet and filling it with hydraulic fluid, hydrostatic extrusion transfers the force from the ram to the billet. Despite the fluid applying triaxial forces, the pressure enhances the billet’s ability to be formed. Sealing the fluid must be considered early to prevent leaks and concerns with reduced pressure.

Even though the hydraulic fluid isolates the wall and billet to eliminate friction, its use in the industry is constrained by a high setup time and poor output rate compared to other extrusion techniques.

The advantages of hydrostatic metal extrusion include

Hydrostatic Metal Extrusion Drawbacks

Generally, the container is vertical during lateral extrusion, and the die is placed on the side. For materials with low melting points, this method works well.

Impact extrusion, limited to softer metals like lead, aluminium, and copper, belongs to the cold extrusion group and is very similar to indirect extrusion. The punch is pushed down quickly and with a lot of force, which causes the slug to extrude rearward, as shown in the schematic.

The distance seen between the punch and the die chamber affects the extrude’s thickness. Using a stripper plate, the extrudates are slid off the punch. Impact extrusions are frequently formed using a mechanical press, which includes the part quickly and over a short stroke.

Due to the extremely high forces operating on the punch and die, tooling must have adequate impact resistance, fatigue resistance, and strength to extrude metal by impact. The flow of the material allows impact extrusion to be categorized into the three categories listed below:

In the case of forward impact extrusion, the metal flows in the direction that the force is applied, but in reverse impact extrusion, it flows in the opposite direction.

The advantages of impact metal extrusion can be

Disadvantages Of Impact Metal Extrusion are

Information